http://www.reliableplant.com/Read/29252/emotional-intelligence-success

What is emotional intelligence (EI)? If you ask this question, you will probably get many different and vague answers. The fact is that the concept of EI in the workplace and the connection between EI and leadership abilities is still being studied.

Since 1990, Peter Salovey and John D. Mayer, who are considered the leading researchers on EI, have defined it as “the subset of social intelligence that involves the ability to monitor one’s own and others’ feelings and emotions, to discriminate among them, and to use this information to guide one’s thinking and actions.” In short, it is the mental ability to reason about emotions, and the capacity to improve thinking and gain better results by using emotions.

Salovey and Mayer have created a model that identifies four factors of emotional intelligence:

These four factors refer to the ability to perceive, control and evaluate emotions. Salovey and Mayer propose that the four factors of their model are prioritized from the more basic psychological processes reflecting the relatively simple abilities of perceiving and expressing emotion to the more complex and conscious higher level reflecting the regulation of emotion.

It is a growing belief that leaders and workers who demonstrate emotional intelligence can go a long way toward helping companies improve productivity and profitability. For example, the department head who is brilliant, has a high IQ and may be an expert in his field can get superior results if he also knows how to stay motivated under stress, motivate others, foster complex interpersonal relationships with employees and clients, and build teams.

Consider the following two examples:

Anna had a high IQ. She showed strong reasoning skills, was analytical and was focused on tasks. She learned new things quickly. However, she discounted how she and others were feeling. She was known to lose her temper if things did not go the way she expected or wanted. She found it difficult or impossible to relate to people who were not as smart as she was and lacked empathy for others. As a result, her ability to be effective in team situations was limited, even though her IQ was very high.

Jose had a high EI. He demonstrated strong interpersonal and intrapersonal relationship skills, making friends easily and managing his emotions well. This made him highly effective in his work, even though there were others who had higher IQs. A key component of his success, his high EI allowed him to consider the emotional component of interactions, using both his cognitive abilities and his understanding of emotions. He was creative and flexible in the face of adversity and resilient after setbacks. As a result, he was able to influence and motivate people because he understood and took into consideration what mattered to them. His authenticity and integrity made him a natural leader.

The above skills are all traits that are shared by leaders with high EI. This then is the link that connects leaders with EI. Evidence is beginning to emerge that leaders with high emotional intelligence tend to demonstrate an open-mindedness that creates generous, people-oriented attributes, helping them to attract and keep great colleagues and employees.

A leader with high EI is more likely to have the ability to align personal and subordinate goals to accomplish company goals. In their book, "The Flight of the Buffalo," James A. Belasco and Ralph C. Stayer cite four responsibilities that a leader must implement at all levels of an organization:

These four principles of leadership responsibility align personal and company goals through emotional intelligence.

A study that shows a direct correlation between high EI within leadership ranks and bottom-line profitability was conducted by Harvard psychologist David McClelland in 1996. He studied a large global food and beverage company and found that division leaders with high EI outperformed yearly earnings by 20 percent, while those without high EI underperformed by the same amount.

The behaviors related to low or no EI can be devastating to the overall health of an organization. In 2002, Fortune magazine ran a series of articles on why companies fail. In one such article titled, "Fearing the Boss More than the Competition," the following was stated: "Sometimes CEOs don't get the information they need to make informed decisions. The main reason, says Daniel Goleman, a psychologist and author of the book 'Primal Leadership,' is that subordinates are afraid to tell them the truth. Even when a boss doesn’t intend to quash dissent, subtle signals – a sour expression, a curt response – can broadcast the message that bad news isn’t welcome. That's why, according to a study by Goleman and two associates, higher-ranking executives are less likely to have an accurate assessment of their own performance."

As an executive and management coach, it has been my personal experience that challenges of the leaders with whom I work are seldom related to lack of technical skills but most often are related to emotional failings; they are too authoritarian, they cannot handle conflict, they generate fear rather than respect, etc.

Since 1990, Peter Salovey and John D. Mayer, who are considered the leading researchers on EI, have defined it as “the subset of social intelligence that involves the ability to monitor one’s own and others’ feelings and emotions, to discriminate among them, and to use this information to guide one’s thinking and actions.” In short, it is the mental ability to reason about emotions, and the capacity to improve thinking and gain better results by using emotions.

Salovey and Mayer have created a model that identifies four factors of emotional intelligence:

- The perception of emotions

- The ability to reason using emotions

- The ability to understand emotions

- The ability to manage emotions

These four factors refer to the ability to perceive, control and evaluate emotions. Salovey and Mayer propose that the four factors of their model are prioritized from the more basic psychological processes reflecting the relatively simple abilities of perceiving and expressing emotion to the more complex and conscious higher level reflecting the regulation of emotion.

It is a growing belief that leaders and workers who demonstrate emotional intelligence can go a long way toward helping companies improve productivity and profitability. For example, the department head who is brilliant, has a high IQ and may be an expert in his field can get superior results if he also knows how to stay motivated under stress, motivate others, foster complex interpersonal relationships with employees and clients, and build teams.

The Difference Between EI and IQ

EI is the ability to use both your emotions and cognitive skills. EI competencies include empathy, intuition, creativity, flexibility, coping, stress management, and intrapersonal and interpersonal skills. In contrast, IQ is a number used to represent the apparent relative intelligence of a person. IQ is the measure of cognitive abilities only (e.g., the ability to learn, the skilled use of reason, the ability to apply knowledge to manipulate one’s environment or to think abstractly as measured by objective criteria such as tests).Consider the following two examples:

Anna had a high IQ. She showed strong reasoning skills, was analytical and was focused on tasks. She learned new things quickly. However, she discounted how she and others were feeling. She was known to lose her temper if things did not go the way she expected or wanted. She found it difficult or impossible to relate to people who were not as smart as she was and lacked empathy for others. As a result, her ability to be effective in team situations was limited, even though her IQ was very high.

Jose had a high EI. He demonstrated strong interpersonal and intrapersonal relationship skills, making friends easily and managing his emotions well. This made him highly effective in his work, even though there were others who had higher IQs. A key component of his success, his high EI allowed him to consider the emotional component of interactions, using both his cognitive abilities and his understanding of emotions. He was creative and flexible in the face of adversity and resilient after setbacks. As a result, he was able to influence and motivate people because he understood and took into consideration what mattered to them. His authenticity and integrity made him a natural leader.

The Connection of EI to Effective Leadership and Organizational Success

Organizations are facing enormous challenges related to the downturn in the economic environment. Today, it is recognized that leadership skills are the most important asset of managers. At the heart of great leadership skills is the ability to develop and maintain interpersonal relationships. These skills include communication, active listening, managing conflict, inspiring and motivating individuals and groups, initiating and managing change, and collaborating and cooperating with other to reach shared goals.The above skills are all traits that are shared by leaders with high EI. This then is the link that connects leaders with EI. Evidence is beginning to emerge that leaders with high emotional intelligence tend to demonstrate an open-mindedness that creates generous, people-oriented attributes, helping them to attract and keep great colleagues and employees.

A leader with high EI is more likely to have the ability to align personal and subordinate goals to accomplish company goals. In their book, "The Flight of the Buffalo," James A. Belasco and Ralph C. Stayer cite four responsibilities that a leader must implement at all levels of an organization:

- Transfer ownership for work to the people who do the work.

- Create an environment that is conducive to the transfer of ownership, a place where each person wants to be responsible for his or her own performance. This means that the leader must paint a clear picture of what great performance looks like for the company and the individual, focusing on performance factors; aligning organization systems, processes and structure to enable successful performance; engaging each individual’s heart, mind and hands in the business of the business; and energizing, motivating and inspiring people around the business focus.

- Develop individual capability and competence.

- Create conditions in the organization that challenge every person to continually learn and grow in skills and knowledge.

These four principles of leadership responsibility align personal and company goals through emotional intelligence.

A study that shows a direct correlation between high EI within leadership ranks and bottom-line profitability was conducted by Harvard psychologist David McClelland in 1996. He studied a large global food and beverage company and found that division leaders with high EI outperformed yearly earnings by 20 percent, while those without high EI underperformed by the same amount.

Danger to Leaders of Emotional Incompetence

Developing emotional intelligence means acknowledging that emotions are always present in the workplace and then consciously doing something intelligent with the emotions. People tend to vary dramatically in the skills to which they use their own emotions and react to the emotions of others. This can be the difference between good leaders and bad leaders.The behaviors related to low or no EI can be devastating to the overall health of an organization. In 2002, Fortune magazine ran a series of articles on why companies fail. In one such article titled, "Fearing the Boss More than the Competition," the following was stated: "Sometimes CEOs don't get the information they need to make informed decisions. The main reason, says Daniel Goleman, a psychologist and author of the book 'Primal Leadership,' is that subordinates are afraid to tell them the truth. Even when a boss doesn’t intend to quash dissent, subtle signals – a sour expression, a curt response – can broadcast the message that bad news isn’t welcome. That's why, according to a study by Goleman and two associates, higher-ranking executives are less likely to have an accurate assessment of their own performance."

As an executive and management coach, it has been my personal experience that challenges of the leaders with whom I work are seldom related to lack of technical skills but most often are related to emotional failings; they are too authoritarian, they cannot handle conflict, they generate fear rather than respect, etc.

The Role of Emotional Intelligence Today

The best leaders employ many tools and have the ability to be flexible in their leadership style, demonstrating situational leadership. There is no question that effective leadership determines the success of an organization. Organizations that place a strong focus on leaders who demonstrate high EI are able to see the results of high-impact leadership behaviors. High-impact leadership can instill trust and passionate commitment to the organization’s goals, mission and vision, especially during today’s turbulent times. It is this commitment that drives success and profitability.About the Author

You are in the engine room of the USS Lincoln. Your job as an oiler is to perform the cleaning and lubrication routes for the steam turbines. You are watching a control panel that monitors all of the ship’s mechanical functions. You have trust that the folks up on the bridge are in agreement about where and how the ship is to travel. All 2,000 sailors rely on the functional teams working in concert to make this voyage a success. You also have faith that this is the finest ship ever built.

You are in the engine room of the USS Lincoln. Your job as an oiler is to perform the cleaning and lubrication routes for the steam turbines. You are watching a control panel that monitors all of the ship’s mechanical functions. You have trust that the folks up on the bridge are in agreement about where and how the ship is to travel. All 2,000 sailors rely on the functional teams working in concert to make this voyage a success. You also have faith that this is the finest ship ever built.

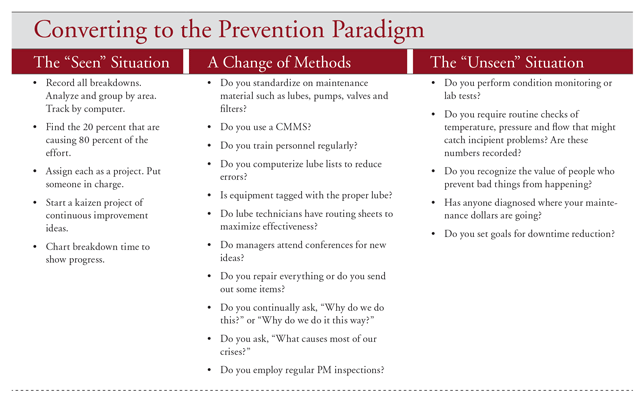

"What is the best way to manage lubrication information for plant assets and their maintenance records?"

"What is the best way to manage lubrication information for plant assets and their maintenance records?"