http://www.machinerylubrication.com/Read/29276/micropitting-surface-fatigue

Many gears can be affected by a phenomenon known as micropitting. This condition is seen when microscopic cracks form on gears and through time and stress result in microscopic pits. These pits grow larger and eventually break away. This can even be a primary failure mode for gears.

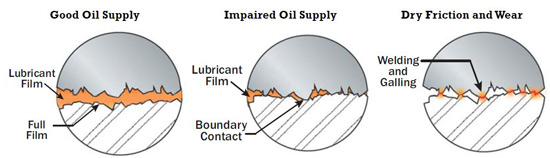

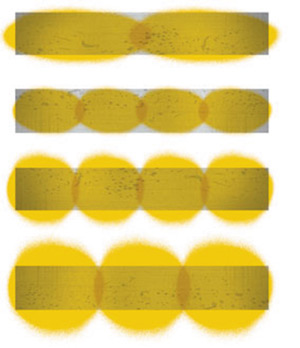

Micropitting generally occurs under elastohydrodynamic lubrication (EHL). When the oil film thickness under EHL becomes too thin at the gear pitchline, surface asperities will begin to come into contact. When these asperities contact each other on opposing surfaces and under high load, they cause elastic or plastic deformation, which leads to micropitting.

| 81% | of lubrication professionals have seen the effects of micropitting or surface fatigue in the gears at their plant, based on a recent survey at machinerylubrication.com |

Surface fatigue is very similar. Under elastohydrodynamic lubrication, surface fatigue often results from denting on a surface due to hard or soft particles. The dents in the surface create what are known as berms. Over time and with repeated high loading, pits develop where the surface breaks apart. With continued high loading, the pits become larger.

The Effects

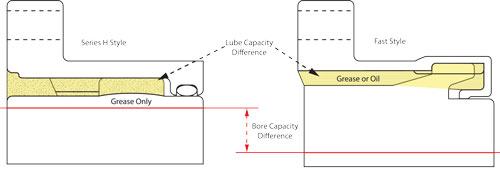

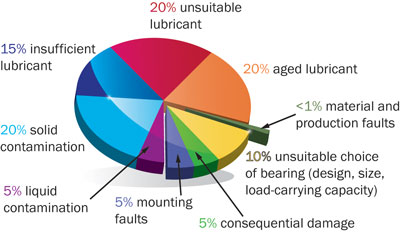

Surface fatigue and micropitting are influenced by the particular lubricant being used, including its base oil, additives, viscosity selection and particle contamination. While micropitting or surface fatigue can occur with synthetic or mineral oil lubricants, synthetics can provide better protection at higher temperatures than mineral oils with the same viscosity grade and additive package. This is due to the fact that synthetics can have a higher viscosity index. In other words, the viscosity of synthetics may change less with an increase in temperature.Although extreme pressure (EP) additives are often necessary, in certain cases they can be very chemically aggressive to surfaces and cause micropitting. These types of additives also become more active with higher temperatures. Some researchers claim oils that do not have EP additives will exhibit a maximum resistance to micropitting. An oil’s ability to protect against micropitting can be determined using the FZG FVA 54 test.

High-viscosity oils also have a greater resistance to micropitting because of their thicker EHL films. However, going to a higher viscosity is not always the best option because it can cause higher operating temperatures, energy loss and/or an increased rate of oil oxidation.

High Risk Contacts

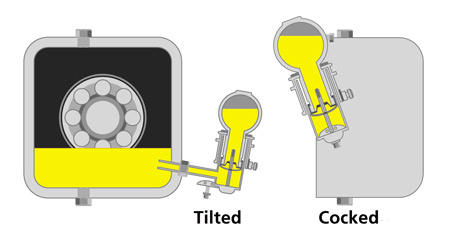

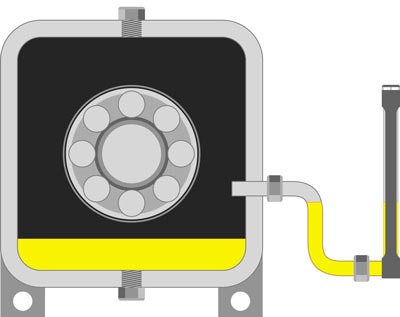

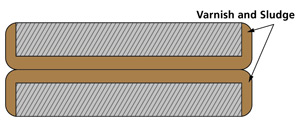

Anywhere rolling contact occurs in machinery there is potential for micropitting and surface fatigue. This would include rolling-element bearings (along the base of the raceway). Gears also have rolling contact, which usually occurs around the pitchline. Cams and rollers are other examples of where you can see rolling contact and thus possible surface fatigue and micropitting.Particles that are much larger than the EHL film thickness can become entrained between surfaces due to a rolling action. Once these particles are in the contact area, they are subjected to massive amounts of contact pressure. Particles with lower compressive strength under this contact pressure can break into smaller pieces, with some embedding in the surfaces and others passing through the contact zone. Harder particles that are larger than the EHL film thickness can pass through the contact zone by denting the softer surface. As mentioned previously, these dents create berms (shoulders) and, over time with more contact pressure, can dislodge from the surface.

Controlling Micropitting and Surface Fatigue

Selecting the right viscosity is key in reducing micropitting and surface fatigue. Higher loads will require higher viscosity, while lower loads allow for lower viscosities. Speed can also have an effect on micropitting and surface fatigue. At lower speeds, the film thickness will decrease. Likewise, at higher speeds, the film thickness can increase. This is another factor to consider in selecting the correct viscosity for your application. The operating temperature also plays a role in micropitting and surface fatigue. As the temperature increases at the contact area, the oil’s viscosity becomes lower and film thickness decreases. As the temperature increases, a lubricant with too low of a viscosity will become thinner and not provide adequate protection, leading to an increased rate of micropitting and surface fatigue. If an EP oil is used, the EP additives become more reactive at higher temperatures and can offer protection from adhesive wear.Of course, too high of a viscosity can also generate excessive heat. This heat that is caused by too high of a viscosity will lead to accelerated oxidation. If oil analysis is not used to determine the remaining useful life and trigger the need for an oil change, the oil will break down and not provide sufficient protection.