http://reliabilityweb.com/articles/entry/lubrication_fmea_the_big_picture/

The global failure modes are:

- Obsolescence (10%)

- Breakage (10%)

- Surface degradation (80%)

The surface degradation causes are:

- Corrosion - Why we paint and use protective coatings

- Wear - Why we lubricate

- Adhesive wear

- Abrasive wear

- Surface fatigue

- Corrosive wear

Obsolescence at 10 percent appears to be growing with rapidly changing technology and increasing government regulations. Do you remember the U.S. government's Cash for Clunkers program? If you operate a coal fired power plant, can you see obsolescence on the horizon?

Breakage, also at 10 percent, is for the design engineers to use FMEA to determine how to handle today's increasing power densities and lighter weights while improving reliability in future process systems and equipment.

Surface degradation at 80 percent is further divided into wear at 65 percent and corrosion at 15 percent. With respect to lubrication, corrosion can be eliminated at this level because paint and protective coatings or stainless steel and other corrosion resistant alloys are used to protect equipment surfaces against environmental damage.

By eliminating 35 percent of the global failure modes, a Tribologist or lubrication engineer can focus on wear when using FMEA. If you don't have a lubrication engineer on your FMEA team, get one! Many organizations do not have an engineer with any formal training in lubrication or tribology - the study and application of the principles of friction, lubrication and wear.

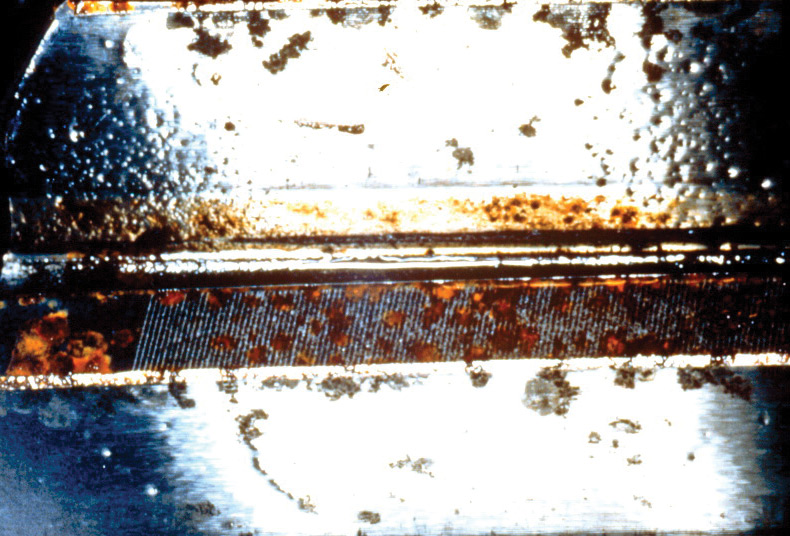

Adhesive Wear

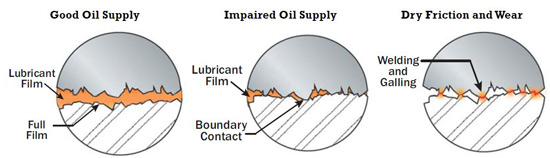

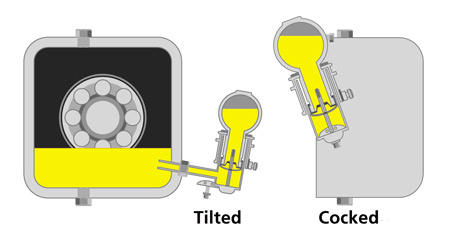

Adhesive wear is a direct result of metal to metal contact. Surface asperities contacting under load while sliding will generate heat, friction and wear due to insufficient or loss of the lubricating film. The range of adhesive wear can be as low as running-in wear with a poorly specified break-in oil up to catastrophic damage with surfaces welded together due to total loss of lubrication.

The most important physical property of a lubricating fluid is viscosity. Viscosity measures a fluid's resistance to flow as it relates to load, temperature and speed. Viscosity determines the ability of the lubricant to enter the contact zone of the moving surfaces and remain in the contact zone under the applied load for the necessary time to prevent metal to metal contact.

Today's equipment design engineers now see the lubricant as an integral component to improve reliability. That is why it is important to read the original equipment manufacturer's manual and review the recommended oils and greases. However, when an existing process or machine is being applied in a new way, any change to the operating load, temperature, or speed must be analyzed to maintain the proper oil film.

Abrasive Wear

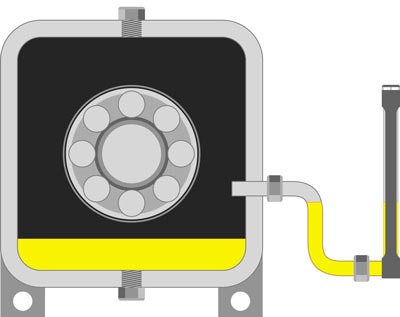

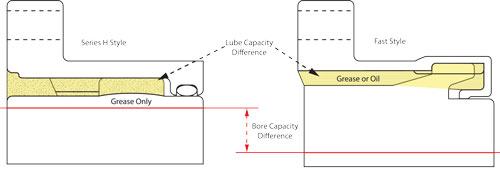

While the saying, "cleanliness is next to godliness," does not appear verbatim in the Bible, it certainly needs to be a commandment for proper lubrication practices. Abrasive wear is caused by suspended hard particles in lubricants. These particles are a combination of wear particles generated by adhesive wear, dirt and other abrasive particles from the process or environment and, in some cases, from the degradation of the lubricant itself. Abrasive wear is why we use filtration and seals.

Never assume a new hydraulic system or piece of machinery is clean and never assume a new lubricant is clean. New machinery and systems must be flushed to remove contaminants that entered during manufacturing and assembly. If you want clean new lubricants, then you must specify the International Organization for Standardization's (ISO) cleanliness requirements for new lubricants and even then, use filtration to transfer the new lube from its container into the reservoir or sump.

Using dirty lubricants affects the entire system or machine because abrasive particles circulate throughout until they are filtered or settle in the reservoir.

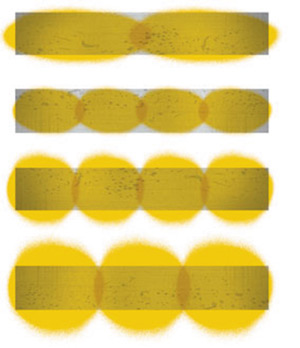

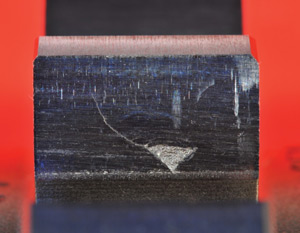

Surface Fatigue

Machinery components do not last forever; they have a designed life for their useful purposes. Premature surface fatigue is usually the result of over-speed or overload of the equipment, especially in the case of bearings and gear surfaces. Even in a perfectly lubricated bearing, if you double the speed, bearing life is reduced by 50 percent and if you double the load, the life is reduced by 87.5 percent.

We are a nation of tinkers and profit-driven to increase system production by making things faster (speed) or doing more work (load) in the same amount of time. By our own actions, surface fatigue has a dotted line impact on why equipment breaks.

Surface fatigue is extremely difficult to detect in operating systems because it is easily masked by catastrophic adhesive wear or catastrophic abrasive wear caused by large chunk spalling. Detection in operating equipment is difficult and typically requires partial disassembly and bore scoping by a trained technician, or direct reading ferrographic analysis of wear particles. In many cases, surface fatigue is only confirmed by complete machine disassembly and inspection of the failed component using magnetic, X-ray, ultrasonic, or scanning electron microscope devices.

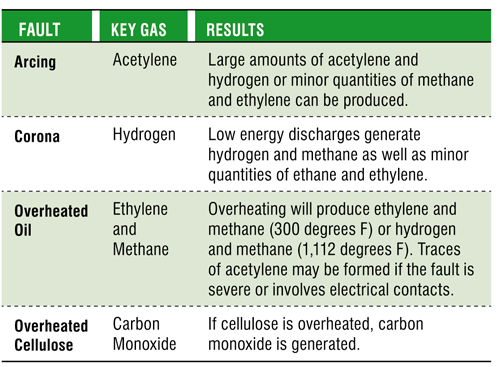

Corrosive Wear

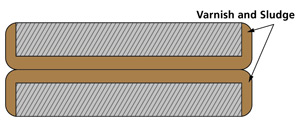

Over time, oxidation causes lubricants to become acidic. Acidic lubricants are responsible for most surface corrosion. This can be measured by the increase in the total acid number (TAN) of the used oil compared to the new lubricant's referenced TAN. In most cases, if the used oil TAN number is 2.5 higher than the new oil's referenced TAN, then the used oil is sufficiently acidic to cause surface corrosion. Oxidation reactions with the lubricant also cause internal deposits of gums, varnish and sludge. Surface corrosion caused by additive reaction is rare. It is generally found in additive reactions with copper or silver surfaces. This is easily detected using elemental oil analysis.

In conclusion, by adding the above risk priority numbers (RPNs) in Figures 2-5, the sum is 65.005% representing the global percentage of equipment failure modes caused by surface degradation. The best way to reduce this global failure mode percentage in your processes and equipment is to improve your lubrication program.

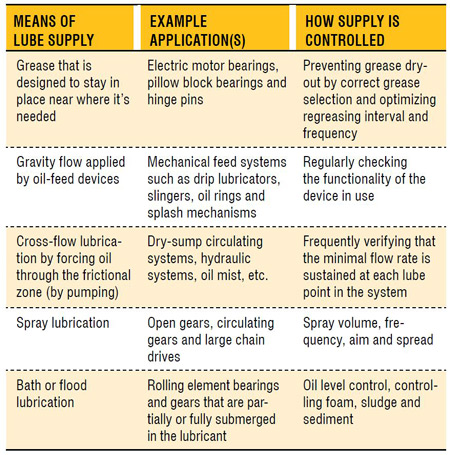

The lubrication program should emphasize the selection of lubricants that must be application driven based on the load, environment, temperature and speed of the process. The lubrication program also must ensure the five basic rights of machinery, which are the right lubricant of the right quality delivered in the right place at the right time in the right amount. Formal lubrication training is needed to establish a truly effective lubrication program. Most organizations require a cultural change in the way they view lubrication fundamentals.

John Cummins is vice president of product technology at Hydrotex®, a manufacturer and distributor of high performance lubricant and fuel improver solutions. He is the Dean of Hydrotex Lubrication University, a comprehensive lubrication education program for the sales field and Hydrotex customers. He is a certified lubrication specialist by the Society of Tribologists and Lubrication Engineers (STLE). www.hydrotexlube.com

John Cummins is vice president of product technology at Hydrotex®, a manufacturer and distributor of high performance lubricant and fuel improver solutions. He is the Dean of Hydrotex Lubrication University, a comprehensive lubrication education program for the sales field and Hydrotex customers. He is a certified lubrication specialist by the Society of Tribologists and Lubrication Engineers (STLE). www.hydrotexlube.com