http://www.reliableplant.com/Read/29299/eam-software-returns

Nobody implements enterprise asset management (EAM) software without an idea of what return they expect on the investment, but too often either due to the selection of inadequate software, subpar implementation or poorly articulated goals, EAM software projects do not deliver a measurable return.

This article will examine a few of the specific ways that EAM software can deliver that sought-after return on investment (ROI) so you can plan your selection and implementation around these deliverables. These five tips should help you take advantage of the cost savings and revenue-enhancement features EAM has to offer while avoiding the pitfalls associated with an overly complex or problematic implementation.

Reduced Maintenance Inventory

As is the case with other types of enterprise software, including enterprise resource planning, inventory reduction is a key area where EAM can deliver a return. Maintenance inventory is just like any other type of inventory. A balance must be struck between excess inventory that ties up capital and outages and downtime that result when a part, consumable or subassembly is required but not available.

Maintenance inventory can be a real challenge to master because in most industrial environments some parts require a long lead-time and cannot be obtained on short notice. That heat exchanger, compressor or motor may be very specific to your individual piece of equipment. So during software selection and implementation, very close attention should be paid to purchasing functionality. Is the purchasing functionality robust enough for advanced and proactive inventory planning and management?

For organizations with multiple locations, special attention should be paid to the extent that inventory can be optimized through standardized part identification and intersite planning. Oftentimes, different locations have different part-naming nomenclatures. Consider the challenge presented a plant manager by a high-value part like a motor that must be stocked at a level of about 0.2. He needs to stock at least one, but if numerous locations around a region require the same part, that one motor could be shared across locations, saving money and preventing unnecessary downtime.

So it should be no secret that inventory reduction is one way the right EAM software can deliver a measurable ROI to your organization.

Manage Cash with Contract Management

Potentially reducing cash tied up in parts is one way the EAM can deliver an ROI, but real-time cash management in general ought to be a top priority. Even when an asset is delivering a positive return in the intermediate term, business still operates on a month-by-month, quarter-by-quarter basis. Real-time information on what it costs to operate a plant or a portfolio of plant assets allows an executive to manage the present rather than adjust for the past.

A significant portion of the variable cost of maintenance operations consists of the cost of contracts for supporting services and materials. EAM ought to take this into consideration and offer integrated contract management. Cash outlays necessary under each contract will be planned as the contract is finalized so cash-flow decisions can be made accordingly.

Some EAM packages allow you to open portals to suppliers like engineering firms and maintenance contractors. As you plan maintenance work for the weeks ahead, if your contractors have visibility of your plans through your EAM system, they can be informed of the upcoming work, schedule their people and ensure that they have the right tools and materials available. This also reduces the amount of time necessary to manage those outside contractors by phone and email.

The lifecycle of a contract with a supplier should be encompassed entirely within the EAM application, starting with the call for bids on the project, acceptance of the bid and then the projected cash outlays and associated work performed by the contractor. This has benefits far beyond cash and contract management.

This also means you save the time involved in entering the record of that work back into the EAM, enterprises resources planning (ERP) or computerized maintenance management (CMMS) software. Moreover, that real-time data could allow for more efficient use of the asset, as in the resumption of a production schedule immediately after a contractor finishes work.

It can also give management notification of when various milestones in a contracted project are completed – milestones that may constitute liquidity events when the contractor is paid. The ability to track these liquidity events is crucial from a cash-management standpoint and contributes to ROI.

Asset Integrity Management and Permitting

EAM can drive cost and risk reduction by acting as a centralized location for all asset data over the entire asset lifecycle. Most managers instinctively know that an as-designed drawing of an asset is different from the as-built drawing. Similarly, the as-maintained drawing will be different from the as-built version. Changes are made during maintenance, refits, lifecycle extensions and repairs just as they are made during construction, and those changes need to be reflected in the asset management system.

An EAM software application should ideally be used to support asset design and construction, enabling the asset data to flow directly into the systems that will be used to sustain, maintain and operate the asset. This approach, known as “Design, Operate, Maintain,” really involves a single asset management system that supports the asset over its entire lifecycle.

The contract-management tools referred to in the section above have a role in true cradle-to-grave support because they ensure that the same enterprise system and data set is used regardless of who is making alterations to the asset.

EAM software must also include integrated permit and incident tracking. For a typical maintenance technician, this level of integration expedites the work that needs to be done and pulls information directly from the EAM system that is necessary to complete a formal work permit. Many EAM applications might not have such a tightly integrated permitting process, forcing technicians to take the time to use a separate system and creating a silo of data that is not reflected in your enterprise application.

Furthermore, someone may forget to get that permit and go into an enclosed area where there may have been a gas leak that was already reported. Eliminating death and disfigurement is certainly one more way EAM software can deliver ROI.

Leverage Integrated Document Management

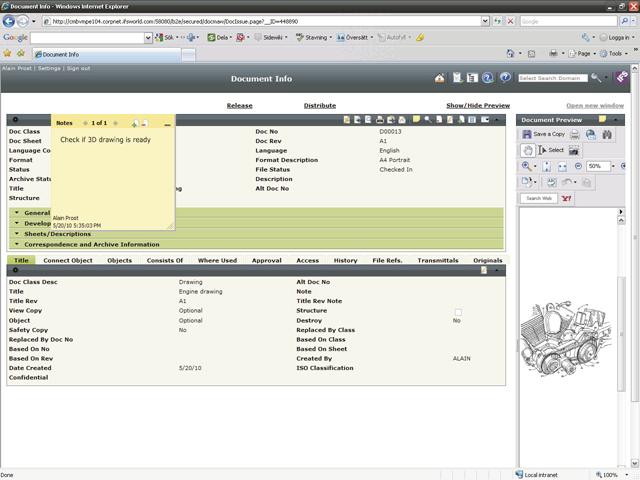

In order to truly manage the asset lifecycle and maximize value realized from that tremendous capital investment, it is critical to have all of your asset data in a single repository. EAM software needs to have integrated document management so as assets are set up in the system, all of the relevant CAD drawings, contracts, maintenance schedules, testing reports and other documents are stored in a central repository. These individual documents must also be linked to the asset object in the EAM system.

In a perfect EAM world, as process manufacturing equipment, oil and gas drilling equipment or other assets are commissioned, managers would be able to take the CAD serialized assets from the builder and pull them directly into their own EAM and document management system. Some EAM packages may be able to import the asset data but lack the hooks into CAD and 3-D CAD systems necessary to fully build those assets out into the system.

This allows the EAM application to be the repository for all asset information over the asset lifecycle. Without that CAD integration, there is still a separate silo for a lot of key asset data that will hamper visibility and decision-making. This really is not in the true spirit of asset lifecycle management, which would keep all asset information together in an organized asset structure.

So apart from ensuring adequate asset integrity management and compliance measures are in place, integrated document management delivers an ROI by reducing the time it takes to find, manage and update documents relating to the asset.

Ease of Implementation and Usability Affect ROI

Fighting human nature is never a smart business strategy, and technicians and other front-line employees will not use a system that is confusing or presents functional barriers to their individual jobs. Therefore, ease of use is critical for an EAM software package. In addition, there is no way anyone can use a system until it has been implemented, so EAM software products that have a history of lengthy or failed implementations are to be avoided.

In many manufacturing environments, EAM software is a secondary or tertiary priority. There is an interest in increasing uptime and efficiency, but in industries like the chemical industry, nuclear power or oil and gas, it is a top priority because you cannot operate assets in a mission-critical environment without absolute control over asset integrity. In these industries, tracking maintenance work is not just about cost or even maximizing asset profitability. You need to be able to mitigate risks by preventing asset failures that could cost lives or cause environmental impacts. Maintenance is critical, and ensuring that the system used to manage and record maintenance work is just as critical.

If EAM software is too convoluted and byzantine, maintenance technicians will not use it, which will present challenges as you will not have visibility into the state of the asset and may not complete essential scheduled maintenance projects. Even a manufacturer in a standard manufacturing environment will realize that an opportunity for ROI is lost if the software that has been licensed and implemented is not broadly used.

One way to increase ROI through usability is to deploy EAM functionality across mobile devices like tablets or through native apps for smartphones. This will allow technicians to update the system in real time, increasing visibility and reducing time spent at a terminal at the end of a shift.

Opportunity for ROI is also increased, and that return can be realized sooner through an EAM application that allows a phased approach to implementation. There are mission-critical elements like work orders, document management to track the specifications of the asset as it is maintained and inventory that can be implemented immediately, allowing safe asset operation. Once that functionality is familiar and absorbed by the operation, additional functionality including permitting, health and safety and even full-blown reliability centered maintenance (RCM) functionality can be implemented.

So it becomes clear that implementation and usability are both potential barriers to realizing ROI on an EAM software investment.

Conclusion

EAM can provide real and measurable cost savings and competitive advantages for companies that select the right set of applications and plan their implementations intelligently. In general, an implementation of EAM software that addresses more of the business functions that support the asset (contract management, inventory, document management and even human resources and finance) will offer a greater return than can be achieved by simply addressing maintenance needs. Care must also be taken to plan the implementation in such a way that it minimizes business disruption and leaves end users with a system they can use comfortably and capably.About the Author

Patrick Zirnhelt is the director of sales for asset-intensive industries for IFS North America. He has more than 17 years of experience working with enterprise systems, which includes software development, implementation and sales. He is a professional engineer who holds a master’s degree in business administration, specializing in management information systems, from the York University Schulich School of Business in Toronto and a bachelor’s degree in mechanical engineering from Queens University in Kingston, Ontario. For information about IFS’ EAM offering, visit www.ifsworld.com/en-na/solutions/enterprise-asset-management-software/.

About the Author

No comments:

Post a Comment